It performs bending strength tests of prism-shaped materials such as borders, beams and parquet under load.

The distance between the lower and upper supports can be adjusted according to the variable structure and sample in accordance with 3 and 4 point tests.

The piston stroke is 75 mm.

The test area area is 300mm.

The measuring weight is 0.01 KN.

Loading Speed can be taken between 0.01 KN/s and 100 KN/s.

It is independent from the body of the Hydraulic Unit.

Test results results can be easily read on the screen automatically or on the computer with the software interface.

LCD unit test can be monitored as instant graph, loading speed, load and stress values.

It will be given together with the test programs.

Computer program:

Program test samples, companies, laboratories and test can be entered.

Test reports and sample reports can be obtained.

The Concrete Beam Flexural Test Press is a device that uses the appropriate apparatus, together with the prism shape of different features and structures, to connect material samples such as curbs, parquet, beams, and to perform protective load strength and bending tests reliably, and is a device that emerges with the assurance of Argon Test.

This device, which is produced in accordance with ASTM, EN and BS systems, can also be tested and examined with this device, which is produced in accordance with the CE standard necessary and important for operator safety and health, via the digital reading unit or over the computer with its software. It is also possible to use it manually.

This device can be used easily even by inexperienced operators thanks to its very useful and simple system.

Use of Concrete Beam Flexural Test Press

Concrete Beam Flexural Test Press Usage

Although the use of this device is extremely simple, there are steps that must be followed in order for correct use. Operators should place the samples with the sample centering apparatus after turning on the device. After the samples are placed, the steps to be taken for the use of the Concrete Beam Flexure Test Press are as follows;

First, if the sample type has been changed, the test parameters must be adjusted, including the velocity ratio.

Then, the test process should be started by pressing the “Start” button on the device control unit.

After pressing the button, the device starts to load automatically thanks to its fast loading pump and performs the loading quickly.

The device automatically changes the test speed depending on the situation, and automatically stops as soon as the sample is broken, completing the test press process.

Concrete Beam Flexural Test Press Features

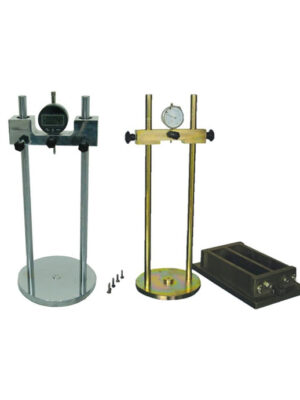

Concrete Beam Flexural Test Press consists of 3 parts: loading body, digital data acquisition control system and automatic hydraulic power unit. As a very functional and useful device, it also has various additional apparatus.

Features of the Concrete Beam Flexural Test Press, which performs the bending and strength tests of all specimens suitable for the device, in the most reliable and consistent way, together with the pressure it applies, and enables the results to be easily examined through the digital screen and stored easily thanks to its software;

It has a 75 mm piston stroke.

It has lower and upper supports whose distances can be adjusted according to the sample and can be changed in accordance with 3 and 4 point tests.

It has a test area height of 300 mm.

It has a measurement accuracy of 0.01 KN.

Loading speed can be adjusted between 0.01-100 KN/s.

It has a hydraulic unit independent of the body.

After the test is terminated, the test results can be read automatically on the digital screen, besides, thanks to its software, it can be read on the computer system as well as the digital unit.

During the test, values such as load, stress, graphics, loading speed can be monitored simultaneously via the LCD unit.

The device is shipped with test programs inside.

Thanks to the computer program, test and sample reports can be obtained.

Reviews

There are no reviews yet.