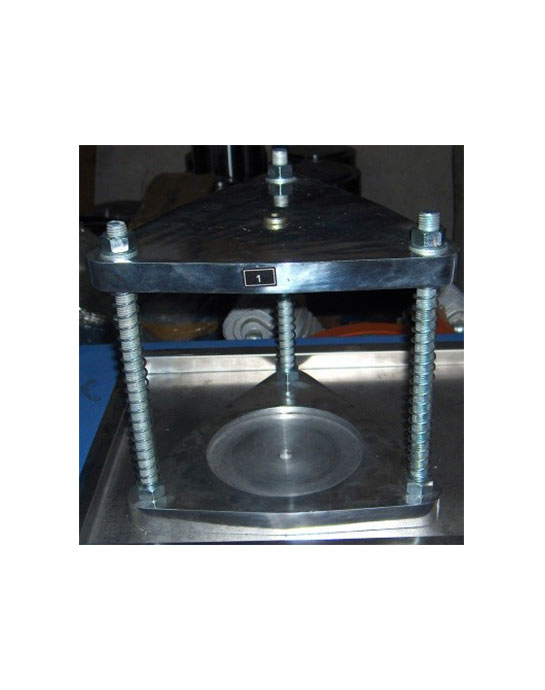

It is used to determine the penetration depth of water into hardened concrete samples under pressure. Provide 3 and 6 sample capacity models. The system can test 150x150x150 mm, 200x200x200 mm cube or 150x300mm cylindrical specimens.

The pressure applied to the sample, up to 12 bar, with an accuracy of 0.2 bar, is generated by compressed air applied to the integrated water tank and controlled by a pressure regulator; with pressure gauge. Water penetration is measured through the burette provided with the system.

The system includes impermeable gaskets for each unit. The equipment must be equipped with a suitable air compressor with a maximum working pressure of 12 bar

| Model | AR-047 | AR-048 |

| Dimensions(mm) | 280x220x710 | 500x500x1800 |

| Weight(kg) | 95 | 106 |

It is used with the Impermeability Test Set to test the results that may occur when fine gravel or sandy substances are exposed to external factors in the laboratory environment. The results that may occur in cases where relatively coarse-grained soils are exposed to water, especially in natural conditions, are determined by the experiments carried out, and thus the deformation that may occur thanks to this set of experiments is determined.

In areas where concrete products will be used, it is very important how durable they are, especially against external factors. Thanks to this test, it has been determined which products should not be used and where, and adverse situations that may occur are prevented beforehand.

The impermeability test set, which is produced in accordance with EN 12390-8 and ISO 7031 standards, has 2 different models. Water penetration depth under pressure is applied on the hardened concrete samples, and 2 different tests are carried out thanks to the models with 3 and 6 sample capacities.

Use of Permeability Test Set

The first of these models is JB-047, with dimensions of 280x220x710 mm and a weight of 95 kg. The other model is JB-048, with dimensions and dimensions of 500x500x1800 mm and a weight of 106 kg.

In these models, 150 x 150 x 150 mm cubes, 200x200x200 mm cubes or 150x30mm cylindrical samples can be tested. The applied water pressure can be increased up to 12 bar and the pressure setting is reduced to 0.2 bar sensitivity. In other words, in this context, the device works with a maximum 12 bar compressor and the results obtained are consistent and reliable thanks to the sealed gaskets inside the device.

Thanks to the manometer on the device, the pressure to be applied can be easily seen and the pressure setting can be changed thanks to this indicator.

The pressure applied can be seen with the manometer mechanism on the device, so the amount of water processed into the sample is easily measured, and the followers are recorded in the device for later measurements. In this context, the manometer is located right next to the device, making it easier to use and thus making it possible for inexperienced operators to use it.

Permeability Test Set Application

Especially the presence of different particles during the test application affects the processing mechanism. During the process, the test is carried out by making the soil 10% or more, and the particles are tested by using the apparatus that passes through the no 200 sieve and also decreases gradually.

At the same time, particles are tested at a constant level in granular soils that remain in memory no. 20 in the operation of the remaining 90% or more particles.

In order to carry out all these processes during the experiment, there are some materials that must be found in the set, and these materials can be listed as follows;

4 permeability cells,

4 tubes,

Water tank,

Ruler

rubber tubes

Thanks to all these materials, the water pressure test can be performed very easily and at the same time, the result of the process obtained is of higher quality.

Reviews

There are no reviews yet.