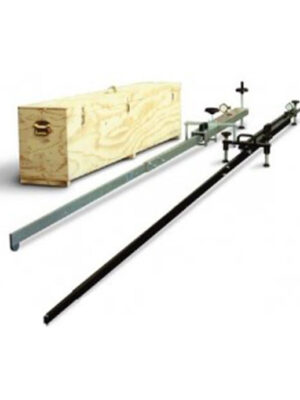

The Marshall Stability Test Machine is used to determine the load and flow values of bituminous mixtures. The AR-005 comprises a compact two column frame with adjustable upper cross beam driven by an electro-mechanical ram with a maximum capacity of 50 kN and a data acquisition and processing system.

The machine can be hand operated by a lateral hand wheel for calibration purposes. The mechanical jack raises the lower cross beam at a constant speed of 50,8 mm/min. The limit switches are provided for the both, bottom and top limit of travel.

The measuring system consists of a 50 kN capacity strain gauge load cell is fitted to the upper cross beam to read stability values and 25 mm x 0.001 mm displacement transducer fitted to the Breaking Head.

Dimensions: 450 x 605 x 960 mm.

Power: 220V 50 Hz.

Weight: 70 kg.

Marshall Stability Device

Within the Marshall Stability Device system, there is a load cell with a capacity of 50 kN, as well as a crushing head, computer interconnect cable and software, and a flow transducer. An optional computer can be added to the Marshall Stability device, which is offered with this system as a standard.

Marshall Stability Device Features

This device, which is loading in its body with a capacity of 50 kN thanks to its motor that provides a rising speed of 50.8 mm per minute, has the dimensions of 450 x 605 x 960 mm and its weight is 70 Kg. The electrical unit is 220 V, 50-60 Hz, 1 ph. Other Marshall Stability Device features are as follows;

It automatically calculates the stability and yield values, and also offers the opportunity to conduct experiments with displacement control.

It provides real-time visualization of the experiments performed in graphic form.

It has the ability to collect 10 data per second at a sample rate for each channel.

There are 3 different system options as ton, kN and lb.

This device can be controlled by connecting to a computer with an Ethernet connection.

What Does the Marshall Stability Device Do?

Marschall Stability Device, which is used to measure the yield and stability values of bitumen coating mixtures, works with an electric motor. In this device, which has a strong and adjustable base and a load cell connected to the bridge, the jack is rotated with the motor connected to the base, and in this way, force is applied to the bitumen coating mixtures.