The jolting table is used for die compaction of 40x40x160 mm cement samples and consists of a die table located on a rotating cam driven at 60 revolutions per minute.

The table drop is 15.0 mm.

The machine is equipped with a counter that automatically shuts off at the end of a preset number of drops.

The weight and dimensions of the shaker fully comply with the requirements of the EN 196-1 standard. Quick clamping and demolding systems make operation simple and quick.

220 volts, 50-60 Hz, 1 phase

Drop height 15mm

RPM 60

Dimensions: 255x285x1000 mm.

Power: 250 watts.

Weight: 55 kg.

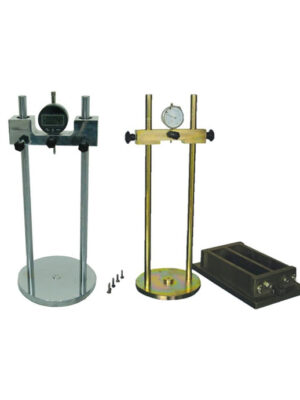

Cement Shaking Table, also known as shock table, is a table that moves at 60 revolutions per minute as a device that enables cement samples to be compressed into the mold. This device, which is used for cement samples measuring 40x40x160 mm, is used to compress the cement material taken into the sample molds and thanks to this device, there is no gap between the mold and the sample.

In this way, the sample, which is made suitable for testing, can be put into the required cement tests without any problems. It is extremely important that the sample transferred to the mold with the help of the funnel is filled and compressed into the sample mold in the best way, in order to give the most accurate results of the test results. In this regard, the Cement Shaking Table (Shock Table) has a very important task and function.

This device, produced in accordance with the EN 196-1 standard, has a suitable use for all dimensions and weights required by this standard. In this way, the sample molds can be easily placed on this table and can be centered and compressed in a very simple and practical way.

Cement Shaking Device (Shock Table) Features

As a device with an electronic counter, the Cement Shaking Device stops automatically when it reaches the required number of hits and completes the process in a short time. It moves at a speed of 60 revolutions per minute in accordance with the standards, and the drop height is determined as 15.0 mm. Besides these features;

The device is determined as 220 V, 50-60 Hz.

The dimensions of the device are 255x285x1000 mm.

The power of the device is 250 W.

The weight of the device is 55 Kg.

This part of the device is covered with a safety sheet in order to avoid any problems with the engine or around the engine.

It is a very reliable device thanks to all the safety precautions being taken.

Having a very practical use, connecting and removing the molds to this device can be performed very easily.

Cement samples are ready for testing both perfectly and quickly thanks to this device.

Although it is extremely durable, the engine and transmission part are designed with the highest quality materials in accordance with the standards.

All necessary information about the electrical mechanisms and conditions of the components is given to you by our company, so you will be able to start using your device in the most correct way.

What Does a Cement Shaking Table (Shock Table) Do?

The Cement Shaking Table (Shock Table) ensures that the cement samples can be compressed into the mold in such a way that there are no gaps and they are centered in the best way possible. Thanks to this device, which is manufactured from the highest quality materials and offered to you at the most affordable prices, as Argon Test, you can get the most accurate results from the test processes to be carried out by compressing your cement samples into the molds in the best way.

With Argon Test quality and assurance, you can have all the devices you need in the Cement Testing Equipment category at the most affordable prices, and you can choose our long-lasting and most practical devices with their special designs.

Reviews

There are no reviews yet.